Hirose Electric Americas

Americas Headquarters

Downer's Grove, Illinois, USA

2001 Butterfield Rd. Suite 1900

Downers Grove, IL 60515

630-282-6700

.jpg?width=600&height=399&name=US_Chicago_Office_2023-(1).jpg)

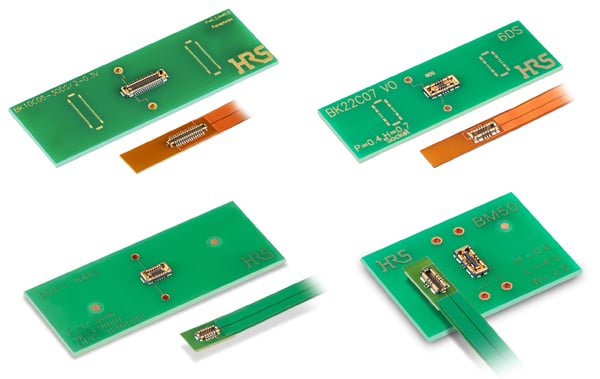

ONE ACTION™

One Action FH™ revolutionizes the connection process by enabling connection through a simple insertion action. Unlike traditional connectors requiring multiple steps to open the actuator, insert the FPC/FFC, and then close the actuator, One Action FH™ completes the connection by inserting the FPC/FFC. This design eliminates the need to touch the actuator, preventing potential damage and ensuring a secure lock upon insertion. The result is a dramatically reduced operation time and fewer steps in the assembly process, cutting down the work time to a third and simplifying the entire procedure.

One Action FH™ is a game-changer in automated assembly, perfectly aligning with the needs of robot-operated production lines. The connector is designed with a large taper at the opening, facilitating smooth insertion of the FPC/FFC. Its unique spring mechanism significantly lowers the insertion force required, enhancing insertion performance. This thoughtful design ensures that One Action FH™ can easily and efficiently operate by humans and robots, making it an ideal choice for modern, automated manufacturing environments where precision and ease of use are paramount.

Downloadable Resources

One Action, Simple and Easy. Download the Pamphlet

One Action FH™ offers unparalleled design flexibility, especially in constrained spaces where traditional connectors may falter. Standard connectors often necessitate actuator operation during the insertion of the FPC/FFC, which becomes challenging in tight spaces or when other components are nearby. One Action FH™, however, requires only the insertion of the FPC/FFC for a complete connection. This feature allows for connections in narrow or limited spaces, making it versatile for various design configurations. The result is increased flexibility in design without compromising on the reliability or quality of the connection.

One Action connectors are designed to minimize assembly errors, especially in high-volume production environments. The simplicity of the insertion process eliminates several steps that are prone to human error in traditional connectors. Reducing the operation to a single action significantly lowers the likelihood of incorrect or incomplete mating. This enhances the production's reliability and maintains consistent quality across large-scale manufacturing.

MICRO / SPACE SAVING

Hirose’s micro-connectors stand out in miniaturized applications for their exceptional balance of compact design and high performance. They offer a unique combination of small footprint, high durability, and excellent electrical characteristics, making them ideal for space-constrained applications without compromising functionality. Additionally, Hirose's connectors focus on user-friendly operation and reliable connectivity, ensuring ease of use and consistent performance. This is crucial in industrial, consumer, automotive, and various vertical applications.

The reliability and quality of Hirose's micro-connectors are unmatched, thanks to their rigorous design and testing standards. Each connector is engineered to withstand harsh environments and repeated use, maintaining integrity over time. Hirose emphasizes precision manufacturing, ensuring tight tolerances and consistent quality across batches. This meticulous attention to detail results in connectors that professionals can trust for critical applications, whether in advanced medical devices, industrial machinery, automotive, or consumer electronics.

One of Hirose's strengths is our ability to customize micro-connectors for specific application needs. We understand that each project has unique requirements, and our team works closely with customers to develop tailored connector solutions. Whether modifying existing designs or creating entirely new configurations, Hirose's expertise in engineering and manufacturing allows for a high degree of customization, ensuring that our connectors perfectly fit the specific technical and spatial constraints of our client's projects.

Hirose is adept at balancing the demands of miniaturization with practical performance and assembly considerations. Our connector solutions are developed holistically, considering electrical and mechanical factors and operation and mating ability. This approach is vital when multiple components are placed on a PCB, requiring thoughtful layering of flexes and connectors. Hirose’s advanced technologies and diverse development capabilities allow us to create groundbreaking solutions that address the space requirements of miniaturized devices while ensuring optimal performance and ease of assembly.

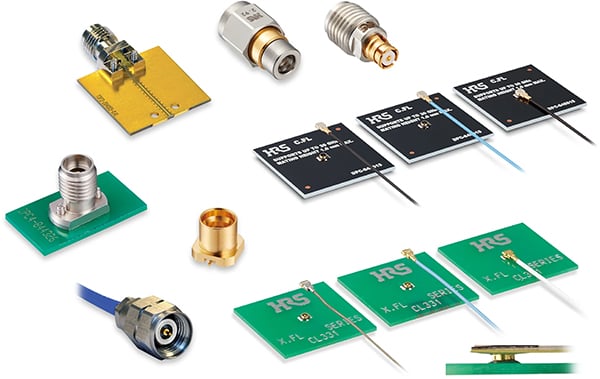

WIRELESS COMMUNICATION

As exemplified by our U.FL SMT Coaxial Connector series, Hirose connectors offer significant advantages in miniaturizing wireless communication devices. They are ultra-small, lightweight, and low-profile, making them ideal for compact equipment. Their nominal mated height of 1.9mm or 2.4mm ensures they fit seamlessly into miniature devices without sacrificing performance, which is crucial for applications in mobile phones, GPS, and wireless LAN systems.

Downloadable Resources

U.FL Series – 1.9mm to 2.4mm Mated Height, Light Weight SMT Micro Coaxial Connector

Our connectors, including our U.FL and X.FL series, are designed to support high-frequency applications essential in modern wireless communication. These connectors can operate effectively up to 8GHz, and with U.FL(A) handling up to 12GHz, they cater to a broad range of devices. Additionally, both U.FL and X.FL connectors exceed the requirements for the latest Wi-Fi standards, ensuring their suitability for the most advanced wireless applications. This high-frequency performance is vital for clear, stable, and fast communication in devices like Bluetooth systems, PDAs, and electronic measuring instruments.

Yes, Hirose connectors are optimized for integration into automated manufacturing processes. The U.FL series, for example, is ideally suited for integration into high-volume pick-and-place SMT manufacturing systems. Their design and packaging facilitate efficient assembly, reducing time and costs, which is particularly beneficial for large-scale production of wireless communication devices.

Security and stability in connections are paramount in Hirose's design philosophy. Our connectors, including the U.FL series, are designed to ensure secure and stable connections. They feature a user-friendly tactile lock for mating and can be easily unmated with a simple extraction tool. Upon mating, this tactile 'click' sensation confirms a fully secure connection, crucial for maintaining consistent performance in wireless communication systems.

Downloadable Resources

Micro Mobility Connector Solutions

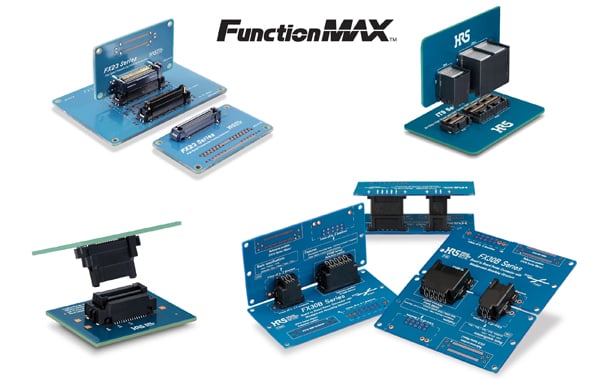

FLOATING / FUNCTIONMAX™

Hirose’s floating connectors are designed to ease alignment challenges in PCB design. Their 'floating' feature allows for a degree of play during mating, accommodating slight misalignments that can occur during assembly. This flexibility is particularly valuable in densely packed or complex multi-connector layouts, where precise alignment can be difficult. It ensures a reliable connection even in challenging assembly conditions, reducing the need for rework and enhancing overall design efficiency.

Yes, Hirose’s floating connectors are built to withstand harsh operating conditions. They are engineered with durable materials and robust construction to endure extreme temperatures, vibrations, and mechanical shocks. This makes them ideal for use in demanding environments like automotive, industrial automation, and outdoor telecommunications equipment, where connectors must maintain performance despite challenging external factors.

Hirose’s floating connectors contribute significantly to streamlining the manufacturing and assembly process. The floating design simplifies the mating process, allowing for quicker and more forgiving assembly, which is especially beneficial in high-volume production. This feature reduces the time and cost associated with assembly, as it lowers the likelihood of connector damage or misalignment issues that could otherwise lead to production delays and increased waste.

Hirose connectors are designed to meet the demands of high-speed transmission required in modern communication systems. They achieve this through optimized terminal pitches, signal contact designs, and material selection that minimize insertion loss and crosstalk while maintaining impedance matching. This attention to detail ensures that Hirose connectors support the latest communication standards, which is crucial for applications in telecommunications and data-intensive fields.

ARMORED DESIGN

Armored connectors are designed with an added layer of protection to withstand harsh physical conditions. They feature reinforced structures that guard against physical damage like impacts, frequent connect/disconnect cycles, and environmental stress. This robust architecture not only extends the life of the connector but also ensures consistent performance in demanding situations. For our customers, this translates to less downtime due to equipment failure, reduced maintenance costs, and the confidence that their electronic devices, whether used in industrial settings or daily consumer products, are reliable and secure. Hirose's armored connectors are an ideal choice when durability and long-term reliability are top priorities.

Hirose's fully armored connector design offers significant advantages in terms of durability and reliability, especially in electronic devices where robustness is critical. The armored design protects the connector from physical damage, such as impacts or misalignment during mating. This enhanced robustness ensures a longer lifespan of the connector and, by extension, the device itself. It's particularly beneficial in portable electronics like smartphones and laptops, where the risk of physical stress is higher.

The fully armored design of Hirose's connectors contributes to device miniaturization by allowing for more efficient use of PCB space. By integrating multiple functions into a single armored connector, there's a reduction in the number of separate components required. This space-saving feature enables OEMs to reduce the product's overall size, add larger batteries for extended life, or incorporate additional functionalities without increasing the device size.

The armored design of Hirose connectors streamlines the manufacturing and assembly process by providing robust yet easy-to-handle components. The enhanced structural integrity of the connectors allows for quicker and more reliable assembly, reducing the risk of damage during the manufacturing phase. This design efficiency is particularly beneficial in high-volume production environments where time and precision are of the essence.

Yes, Hirose's armored connectors are well-equipped to handle the demands of high-speed digital and RF signal transmission. The robust armored design does not compromise the connector's performance capabilities. These connectors support various high-frequency applications, ensuring optimal signal integrity and performance. The design facilitates effective VSWR (Voltage Standing Wave Ratio) across different frequency ranges, making them suitable for advanced applications in telecommunications, computing, and other high-speed digital domains.